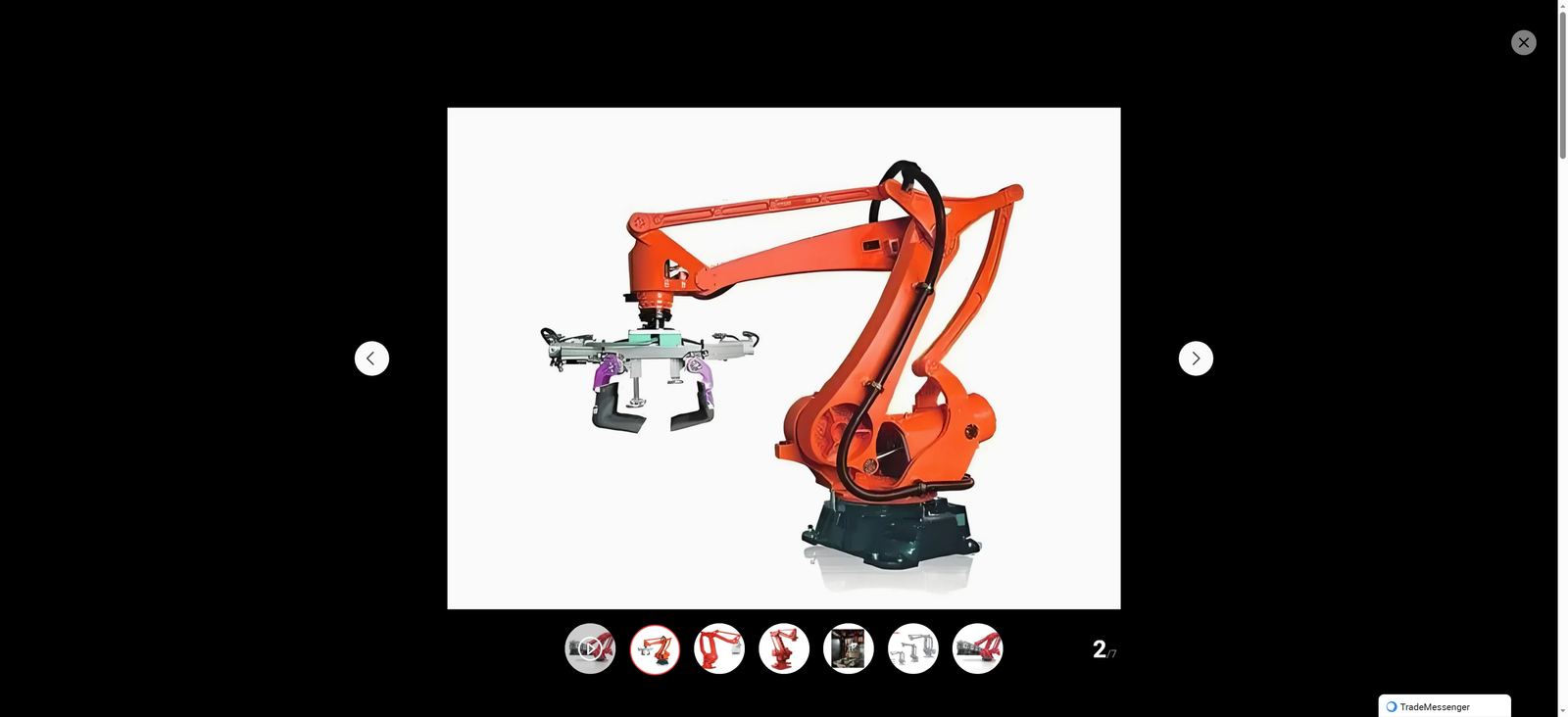

YSR-4-120-F 3150 Automatic Stacking Machine with Robot Palletizer: Redefining Efficient and Intelligent Palletizing Solutions

In the era of intelligent manufacturing, the demand for high-efficiency, high-precision and low-cost material handling equipment is increasingly prominent. As a core equipment in the logistics and production link, automatic stacking machines with robot palletizers have become a key force in promoting the transformation and upgrading of enterprises. The YSR-4-120-F 3150 Automatic Stacking Machine with Robot Palletizer, with its advanced technical design, stable operation performance and wide application adaptability, has emerged as a star product in the field of automatic palletizing, providing high-quality solutions for enterprises in various industries to improve production efficiency and optimize operation management.

The YSR-4-120-F 3150 Automatic Stacking Machine with Robot Palletizer is a high-end intelligent equipment integrating mechanical design, electrical control, automatic detection and robot technology. It is carefully developed on the basis of in-depth research on market demand and industry pain points, adhering to the design concept of "efficiency, stability, intelligence and environmental protection". The product not only has a compact and reasonable structure, but also has excellent performance in terms of operation accuracy, stacking efficiency and equipment reliability, which can fully meet the diversified palletizing needs of enterprises for different specifications, materials and packaging forms of products.

One of the core advantages of the YSR-4-120-F 3150 Automatic Stacking Machine with Robot Palletizer is its high-efficiency operation performance. Equipped with a high-performance robot palletizer and a professional automatic stacking system, the equipment can realize fully automatic operations from product conveying, positioning, grabbing to stacking, pallet changing and other links, without manual intervention. With a designed stacking capacity of up to 120 pieces per minute and a maximum load capacity of 3150kg, the YSR-4-120-F 3150 can significantly improve the palletizing efficiency of enterprises, effectively solve the problems of low manual stacking efficiency, high labor intensity and easy error, and help enterprises achieve large-scale and continuous production. Compared with traditional manual stacking, the equipment can increase production efficiency by more than 3 times, while greatly reducing the labor cost of enterprises.

In addition to efficient operation, the high-precision control and stable reliability of the YSR-4-120-F 3150 are also highly recognized by the market. The equipment adopts an advanced servo control system and a high-precision positioning sensor, which can realize precise positioning and grabbing of products, with a stacking accuracy error of less than ±2mm, ensuring that the stacked goods are neat, stable and not easy to collapse, effectively reducing the loss of goods during storage and transportation. At the same time, the key components of the equipment, such as the robot arm, reducer and conveyor belt, are all selected from well-known international brands, which have the characteristics of high wear resistance, strong load-bearing capacity and long service life. After strict quality testing and long-term operation verification, the equipment has a low failure rate, stable operation performance and can adapt to the long-term continuous operation needs of industrial sites.

The strong adaptability and flexible configuration of the YSR-4-120-F 3150 make it widely used in various industries. Whether it is bags, boxes, barrels, plates and other different forms of packaging products, or different specifications and materials of goods, the equipment can be flexibly adjusted and adapted through parameter setting and fixture replacement. It is widely used in food and beverage, chemical industry, building materials, logistics, medicine, automobile parts and other industries. For example, in the food and beverage industry, it can realize the automatic stacking of rice bags, flour bags, beverage cases and other products; in the chemical industry, it can complete the safe stacking of chemical barrels, chemical bags and other dangerous goods; in the logistics industry, it can efficiently handle the stacking and sorting of various cartons and parcels. The flexible application characteristics enable the equipment to meet the personalized production needs of different enterprises, with strong market competitiveness.

Intelligent operation and management is another major highlight of the YSR-4-120-F 3150. The equipment is equipped with a humanized man-machine interface, which adopts a touch screen operation mode, with simple and intuitive operation and clear interface. Operators can complete parameter setting, operation control, fault inquiry and other operations through the touch screen without professional technical training. At the same time, the equipment supports remote monitoring and intelligent management functions. Through the connection with the enterprise's MES system, managers can real-time monitor the operation status, production data, fault information and other data of the equipment, realize the unified management and scheduling of the equipment, and lay a foundation for the enterprise's digital and intelligent production management. In addition, the equipment is also equipped with a complete safety protection system, including emergency stop buttons, safety doors, infrared sensors and other safety devices, which can effectively prevent safety accidents and ensure the safety of operators and equipment.

In terms of energy conservation and environmental protection, the YSR-4-120-F 3150 also performs well. The equipment adopts an optimized energy-saving design, which can effectively reduce energy consumption during operation. Compared with similar products, it can save more than 15% of energy. At the same time, the equipment operates with low noise and low vibration, which can reduce the impact on the working environment and meet the environmental protection requirements of modern enterprises. The energy-saving and environmental protection characteristics not only help enterprises reduce operation costs, but also conform to the development trend of green manufacturing.

Since its launch, the YSR-4-120-F 3150 Automatic Stacking Machine with Robot Palletizer has won wide praise from customers with its excellent performance, stable quality and perfect after-sales service. A large number of application cases have proved that the equipment can effectively help enterprises improve production efficiency, reduce labor costs, enhance product quality stability and improve market competitiveness. Whether it is a small and medium-sized enterprise or a large-scale manufacturing enterprise, the YSR-4-120-F 3150 can bring significant economic benefits and social value.

Looking forward to the future, with the continuous deepening of intelligent manufacturing, the demand for automatic palletizing equipment will continue to grow, and higher requirements will be put forward for the performance, intelligence and integration of equipment. The YSR-4-120-F 3150 Automatic Stacking Machine with Robot Palletizer will adhere to the concept of continuous innovation, keep pace with the times, continuously optimize product design and upgrade technical level, and launch more high-quality, efficient and intelligent palletizing solutions to help more enterprises realize the transformation and upgrading of intelligent production and make greater contributions to the development of the global intelligent manufacturing industry.