Xbot Agv300: Redefining Efficient Material Handling in Industrial Logistics

In the era of intelligent manufacturing, the demand for efficient, accurate and low-cost material handling in industrial logistics has become increasingly prominent. As a core equipment in smart factories and workshops, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are gradually replacing traditional manual handling, injecting strong momentum into the transformation and upgrading of the manufacturing industry. Among them, the Xbot Agv300 300kg Transport Handling Robot stands out with its stable performance, flexible operation and high adaptability, becoming a reliable partner for enterprises in industrial logistics transmission, delivery and material handling.

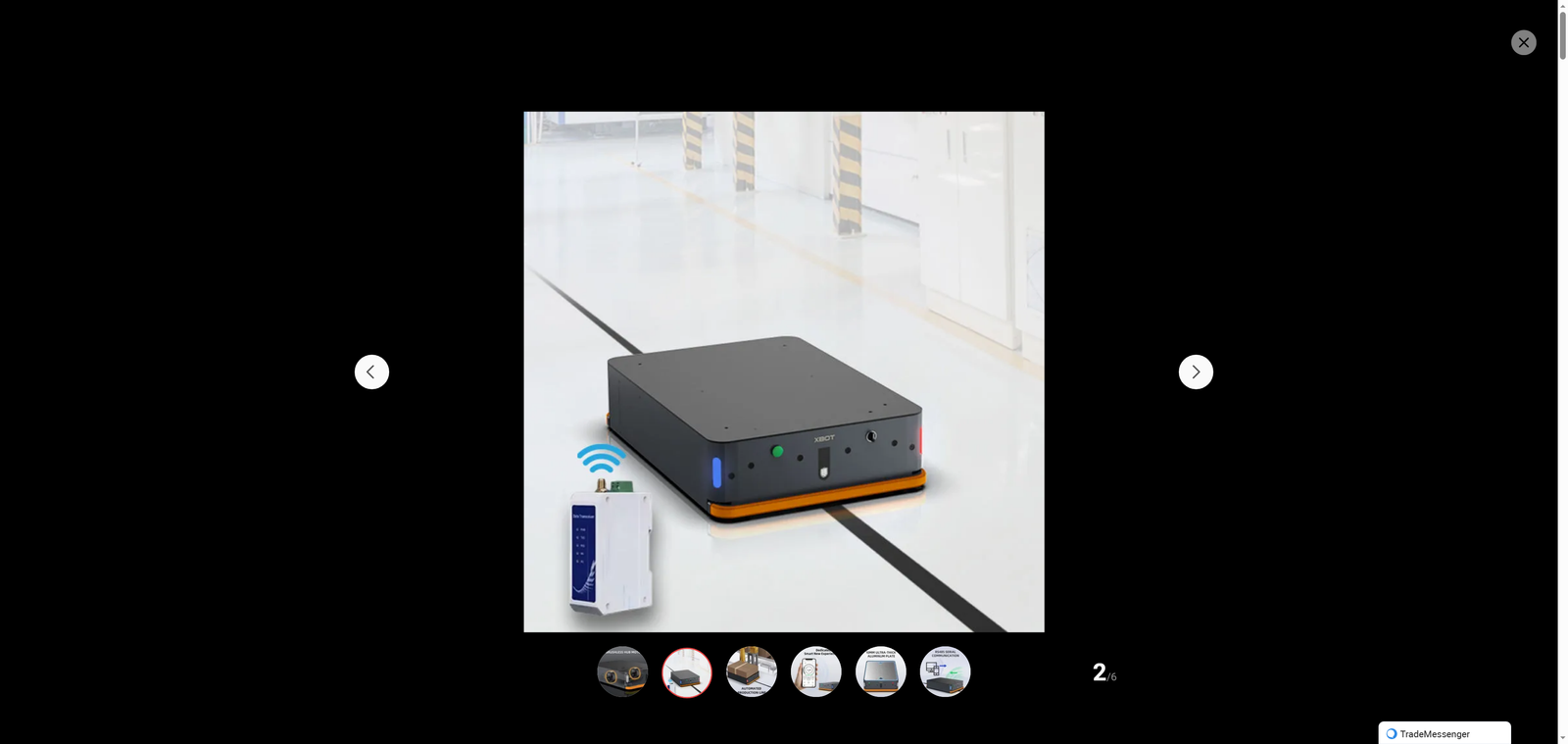

The Xbot Agv300 is a high-performance industrial logistics robot specially designed for 300kg load scenarios, integrating advanced navigation technology, precise motion control and intelligent scheduling systems. Unlike traditional handling equipment that relies on fixed tracks, this AMR adopts multi-sensor fusion navigation technology, including laser SLAM, visual navigation and ultrasonic obstacle avoidance. It can automatically build maps, plan paths and adjust routes in real time in complex workshop environments, without the need for manual intervention or infrastructure transformation, greatly reducing the difficulty and cost of project landing.

Stability and reliability are the core advantages of the Xbot Agv300. Targeting the 300kg load demand in industrial scenarios, the robot has undergone rigorous structural optimization and load-bearing testing. Its high-strength body frame and high-quality driving wheel assembly can stably carry various materials such as raw materials, semi-finished products and finished products, and maintain smooth operation even on uneven ground. At the same time, the robot is equipped with a dual-redundancy safety protection system, including emergency stop buttons, anti-collision sensors and warning lights. Once an obstacle is detected or an abnormal situation occurs, it can quickly stop or detour, effectively ensuring the safety of personnel, equipment and materials in the workshop.

Flexibility and intelligence are the key highlights that distinguish the Xbot Agv300 from traditional AGVs. As an advanced AMR, it supports multiple task modes such as point-to-point transportation, automatic loading and unloading, and multi-robot collaboration. Through the intelligent scheduling platform, managers can remotely assign tasks, monitor the robot's operating status, and view work logs in real time, realizing centralized management and efficient scheduling of multiple robots. In addition, the Xbot Agv300 has strong compatibility and can be seamlessly connected with the factory's MES, WMS and other information systems. It can automatically obtain material information, order tasks and storage locations, realizing full-process information visualization and intelligent integration of logistics links.

The Xbot Agv300 has a wide range of application scenarios in industrial logistics, covering factories, workshops, warehouses and other places. In the automobile parts manufacturing workshop, it can automatically transport engines, gearboxes and other heavy parts between production lines, reducing manual handling intensity and avoiding potential safety hazards; in the electronic product assembly factory, it can accurately deliver components to each workstation according to production plans, improving production efficiency and order fulfillment rate; in the logistics warehouse, it can realize automatic loading and unloading of goods, storage and retrieval, and short-distance transportation, reducing warehouse operating costs and improving space utilization. Whether it is a single-point handling task or a complex multi-link logistics process, the Xbot Agv300 can adapt to different needs and provide personalized solutions for enterprises.

In the context of the rapid development of intelligent manufacturing, the Xbot Agv300 300kg Transport Handling Robot is not only a tool to improve logistics efficiency, but also an important carrier for enterprises to realize digital transformation. By introducing this robot, enterprises can significantly reduce manual labor costs, improve handling accuracy and work efficiency, reduce material damage and safety accidents, and further optimize the production logistics process. At the same time, the data collected by the robot during operation can provide valuable decision-making basis for enterprises to optimize production plans, adjust logistics routes and improve management levels, helping enterprises to enhance their core competitiveness in the fierce market competition.

Looking to the future, with the continuous progress of technology and the deepening of intelligent manufacturing, the application of industrial logistics robots will become more and more extensive. As a leading product in the field of 300kg load AMR, Xbot Agv300 will continue to adhere to technological innovation, continuously optimize product performance and expand application scenarios, and provide more efficient, intelligent and reliable logistics handling solutions for global manufacturing enterprises. It will work with enterprises to build a smarter, more efficient and greener industrial logistics system, and contribute to the high-quality development of the manufacturing industry.