Commercial Electric Candy Floss Robot: A Sweet Game-Changer for Amusement Parks

Amusement parks are always in pursuit of creating joyful, efficient and memorable experiences for visitors, where food and fun go hand in hand. Among the various iconic snacks that define the amusement park vibe, cotton candy—with its fluffy texture, vibrant colors and sweet aroma—has long been a favorite for both kids and adults. In recent years, the commercial electric cotton candy robot has emerged as a revolutionary upgrade to the traditional cotton candy stand, redefining the way amusement parks offer this beloved treat. More than just a vending machine, it is a perfect combination of technology, efficiency and entertainment, becoming a must-have "sweet asset" for modern amusement parks.

Compared with the traditional manual cotton candy making mode, the commercial electric cotton candy robot has obvious advantages in efficiency and stability, which perfectly meets the high-demand operation scenario of amusement parks. During peak seasons or holidays, amusement parks often face long queues in front of snack stalls, and manual production—limited by the speed and physical strength of the operator—can easily lead to visitor complaints and missed business opportunities. The electric cotton candy robot, powered by a high-performance motor and intelligent control system, can complete a standard cotton candy in 60 to 90 seconds, with a daily output of up to 500 servings. It runs continuously for 8 to 10 hours without fatigue, ensuring stable supply even during the busiest periods. Moreover, the robot’s production process is highly standardized: the amount of sugar, spinning speed and heating temperature are all precisely controlled by programs, avoiding the inconsistency in taste and shape caused by manual operation. Every cotton candy made by the robot is fluffy, evenly colored and moderately sweet, maintaining consistent quality that wins the trust of visitors.

Hygiene and safety are another key highlight of the commercial electric cotton candy robot, which aligns with the strict health management requirements of amusement parks. Traditional manual cotton candy making involves direct contact between the operator’s hands and the raw materials and finished products, posing potential risks of bacterial contamination. In contrast, the electric cotton candy robot adopts a fully enclosed production structure: the sugar storage box, heating chamber and spinning mechanism are all isolated from the external environment, and the entire production process is completed automatically without manual intervention. The robot is equipped with a detachable and washable food-grade stainless steel component, which is easy to clean and disinfect, effectively preventing cross-contamination. In addition, the robot is equipped with multiple safety protection devices, such as overheating protection, power-off protection and anti-clogging functions, which not only ensure the safety of the equipment operation but also eliminate potential hazards such as scalds caused by manual operation. For amusement parks, which attach great importance to public health and safety, the robot’s hygienic design not only reduces the pressure of health supervision but also enhances the park’s brand image in the minds of visitors.

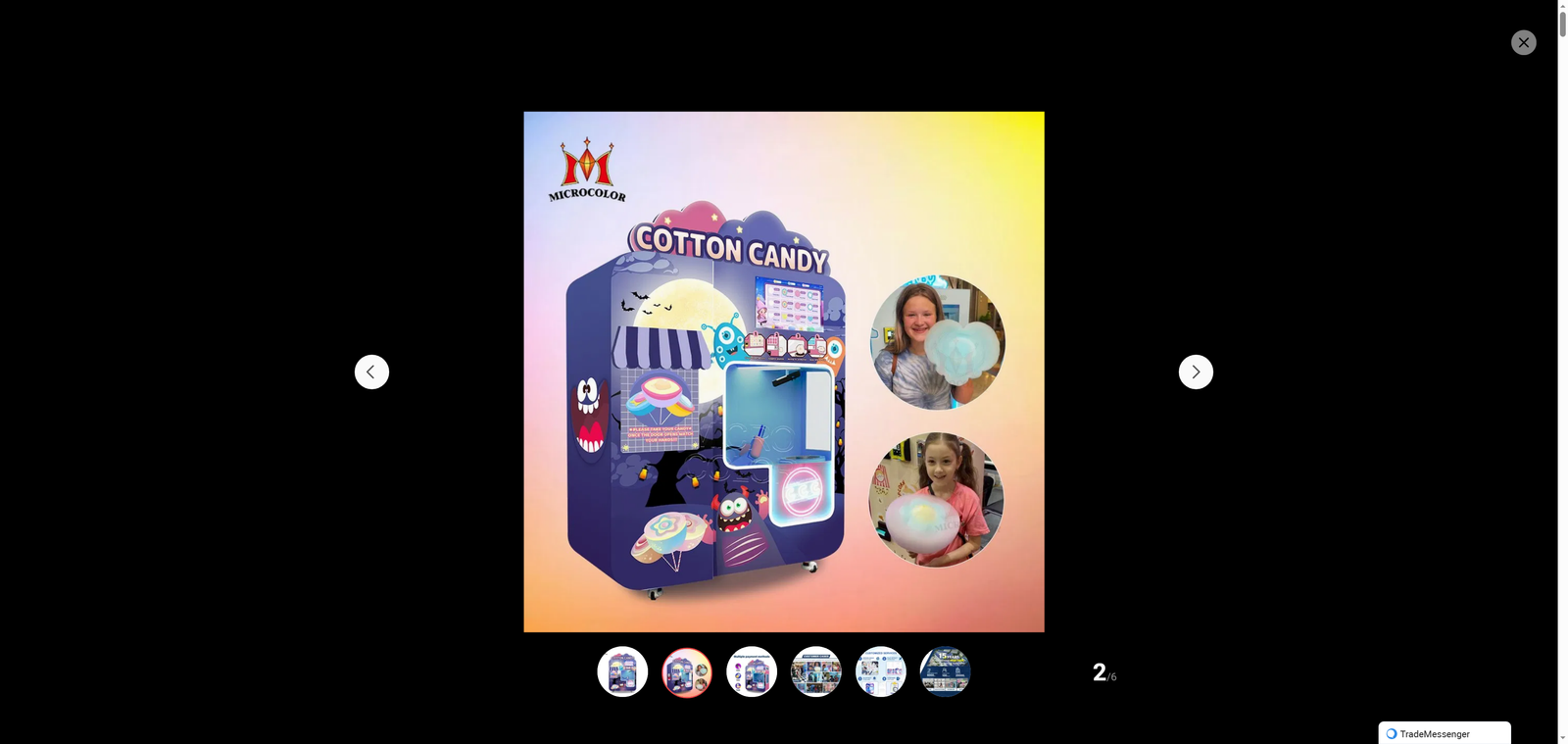

Beyond practicality, the commercial electric cotton candy robot also adds a strong entertainment attribute to amusement parks, becoming a new "check-in spot" that drives passenger flow. Unlike the monotonous manual production process, the robot’s spinning action—with its fast-rotating head and the gradual formation of fluffy cotton candy—is full of visual appeal. Many models are designed with colorful LED lights, dynamic music and interactive screens: when the robot is making cotton candy, the lights flash in sync with the music, and the screen plays interesting animations or prompts visitors to scan the code to participate in mini-games. Some high-end models even support custom patterns: visitors can choose their favorite cartoon characters, park logos or text on the interactive interface, and the robot can spin the cotton candy into the corresponding shape. This personalized and interactive experience not only satisfies the children’s curiosity and sense of participation but also attracts young people to take photos and share on social media, forming spontaneous publicity for the amusement park. In fact, many amusement parks have found that after introducing the cotton candy robot, the surrounding areas have become popular check-in areas, driving the flow of people to other nearby facilities and increasing the overall consumption volume of the park.

From the perspective of operational cost, the commercial electric cotton candy robot also brings long-term economic benefits to amusement parks. Although the initial investment of the robot is higher than that of a traditional manual stand, its long-term operation cost is significantly lower. On the one hand, it saves the labor cost: one robot can replace 2 to 3 manual operators, and there is no need to pay wages, social security or other labor-related expenses. On the other hand, it reduces the raw material waste: the intelligent control system of the robot can accurately control the amount of sugar used for each cotton candy, reducing the waste caused by manual over-sugar or under-sugar. In addition, the robot has a long service life—usually 5 to 8 years—with low maintenance costs, as most components are wear-resistant and easy to replace. For amusement park operators, the robot is not only a production tool but also an investment that can generate continuous returns. It helps to optimize the cost structure, improve the profit margin of snack business, and bring more economic benefits to the park.

With the continuous upgrading of the amusement park industry and the growing demand for intelligent and high-quality services, the commercial electric cotton candy robot is no longer a "novelty" but a "necessity" for park operation. It solves the pain points of traditional cotton candy sales such as low efficiency, poor hygiene and high cost, and at the same time creates new value in entertainment and brand promotion. Whether it is a large-scale theme park, a urban amusement park or a water park, the electric cotton candy robot can adapt to different scenarios and meet the diverse needs of visitors. It is not just a machine that makes cotton candy, but a carrier of joy that integrates technology and sweetness, adding more color to the amusement park experience.

In the future, with the development of artificial intelligence and Internet of Things technology, the commercial electric cotton candy robot will be more intelligent and humanized: it may realize automatic inventory management, predict sales volume according to passenger flow data, and even connect with the park’s membership system to provide personalized preferential services. Undoubtedly, this "sweet robot" will continue to lead the innovation of amusement park catering services, bringing more surprises to visitors and creating greater value for amusement park operators.