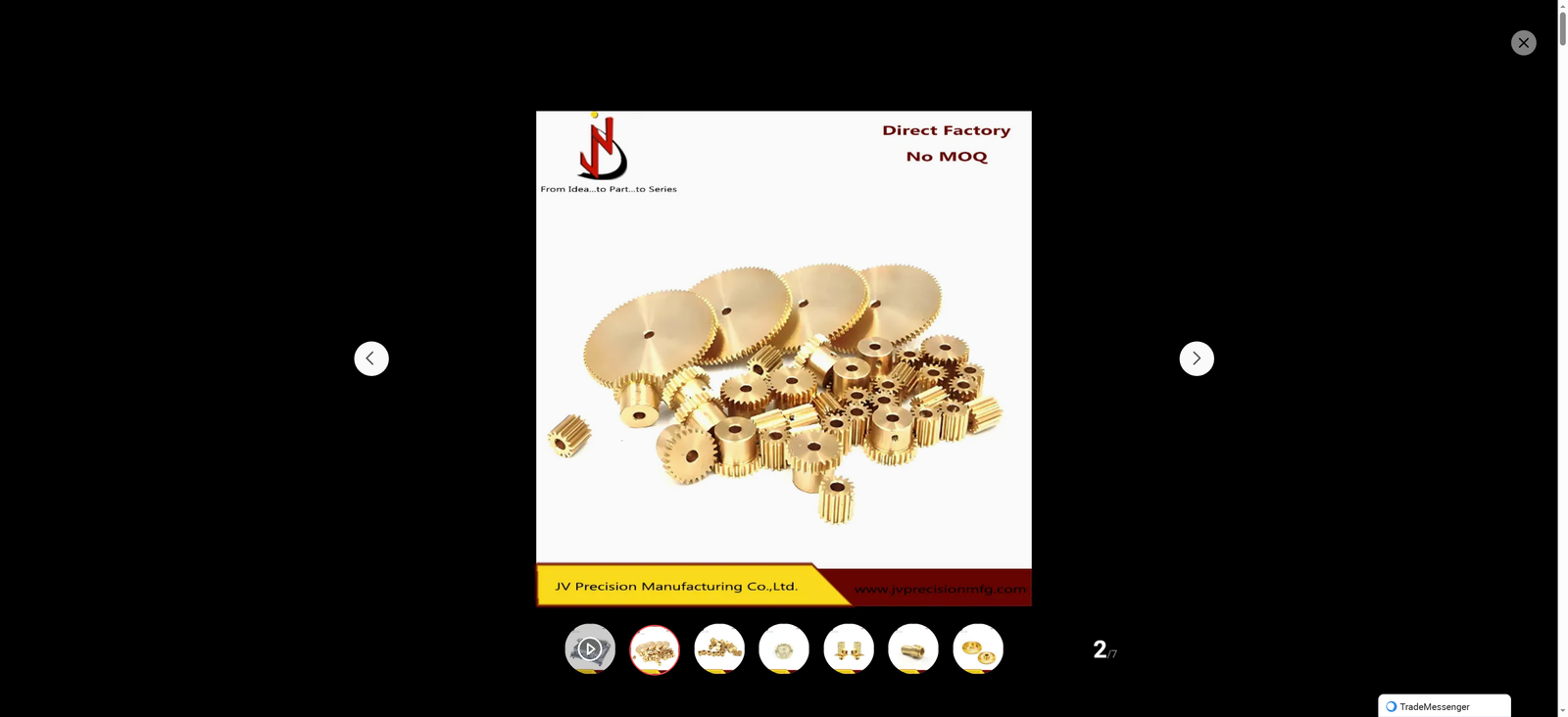

CNC-Machined Brass, Bronze & Copper Gearbox Parts: The Core Power of Quiet Robot Arm, Motor, Pump & Engine

In the era of intelligent manufacturing and precision machinery, the performance of core components directly determines the operational efficiency, stability and noise control level of equipment. Among them, gearbox parts, as the "power transmission core" of mechanical equipment, play an irreplaceable role in converting speed, transmitting torque and ensuring smooth operation. CNC-machined brass, bronze and copper gearbox parts, with their excellent material properties and high-precision processing advantages, have become the preferred choice for key equipment such as quiet robot arms, motors, pumps and engines, injecting reliable power into the high-quality development of the machinery industry.

Brass, bronze and copper, as classic non-ferrous metal materials, have their own unique advantages that make them ideal for manufacturing gearbox parts. Brass, an alloy of copper and zinc, has excellent machinability, good wear resistance and corrosion resistance, and its moderate hardness and ductility ensure that it can be accurately processed into complex gear shapes while maintaining stable transmission performance. Bronze, especially tin bronze and aluminum bronze, has superior wear resistance, fatigue resistance and load-bearing capacity, and its friction coefficient is relatively low, which can effectively reduce noise during transmission—this is crucial for the demand of quiet equipment such as robot arms. Copper, with its excellent thermal conductivity, can quickly dissipate the heat generated during the operation of the gearbox, avoiding overheating damage to parts and improving the service life of the equipment. These material advantages lay a solid foundation for the high performance of CNC-machined gearbox parts.

The application of CNC machining technology further releases the potential of brass, bronze and copper materials, making gearbox parts achieve higher precision, better consistency and more complex structures. CNC machining, with its numerical control programming and automatic processing characteristics, can realize high-precision cutting, milling, drilling and other operations on metal blanks, with machining accuracy up to ±0.001mm. For gearbox parts such as gears, shafts, sleeves and housings, which have high requirements for dimensional accuracy and surface roughness, CNC machining can ensure that each part meets the design standards, reducing the fit gap between parts and thus reducing vibration and noise during operation. In addition, CNC machining has strong flexibility, which can quickly adapt to the processing needs of different specifications and types of gearbox parts, whether it is small-batch customized parts for robot arms or mass-produced parts for motors and pumps, it can efficiently complete the processing tasks, improving production efficiency and product quality stability.

In the field of quiet robot arms, CNC-machined brass, bronze and copper gearbox parts have become the core components to realize precise and quiet operation. Robot arms are widely used in industries such as automobile manufacturing, electronic product assembly and precision machining, which require high positioning accuracy and low noise during operation to avoid affecting the processing quality and working environment. The gearbox parts made of brass and bronze have low friction and good wear resistance, which can reduce the noise generated by gear meshing; at the same time, the high precision of CNC machining ensures the smooth meshing of gears, avoiding vibration caused by excessive fit gap, thus realizing the quiet operation of the robot arm. In addition, the corrosion resistance of copper alloy parts can ensure the stable operation of the robot arm in different working environments, extending its service life.

For motors, pumps and engines, CNC-machined brass, bronze and copper gearbox parts are important guarantees for improving equipment efficiency and reducing noise. Motors are the power source of various mechanical equipment, and the gearbox is responsible for adjusting the speed and torque to meet the working needs of the equipment. Brass gearbox parts have good conductivity and thermal conductivity, which can help the motor dissipate heat in time and ensure stable operation; bronze gear parts have strong load-bearing capacity, which can adapt to the high torque transmission requirements of the motor. Pumps, as fluid transportation equipment, require the gearbox to have good sealing and wear resistance to avoid fluid leakage and improve transportation efficiency. Copper alloy parts have excellent corrosion resistance to various fluids, and CNC-machined precision parts can ensure the sealing performance of the gearbox. Engines, especially small and medium-sized engines, have high requirements for the reliability and durability of gearbox parts. The fatigue resistance and wear resistance of bronze and brass parts can cope with the high-frequency vibration and high-temperature environment during engine operation, ensuring the long-term stable operation of the engine and reducing maintenance costs.

In addition to the above application fields, CNC-machined brass, bronze and copper gearbox parts also show unique advantages in aerospace, medical equipment, marine equipment and other fields. In aerospace equipment, the lightweight and high-strength characteristics of copper alloys can reduce the overall weight of the equipment while ensuring performance; in medical equipment, the high precision and low noise of parts can meet the strict requirements of medical operations; in marine equipment, the corrosion resistance of copper alloys can resist the erosion of seawater and extend the service life of the equipment.

With the continuous development of intelligent manufacturing, the requirements for mechanical equipment in terms of precision, efficiency, noise control and service life are getting higher and higher. CNC-machined brass, bronze and copper gearbox parts, with their excellent material properties and high-precision processing quality, will play a more important role in the upgrading and development of the machinery industry. In the future, with the continuous progress of CNC machining technology and the continuous optimization of copper alloy materials, these gearbox parts will be more precise, more durable and more environmentally friendly, providing strong support for the development of high-end equipment manufacturing industry.

In conclusion, CNC-machined brass, bronze and copper gearbox parts are the core components of quiet robot arms, motors, pumps and engines. Their unique material advantages and high-precision processing characteristics not only ensure the stable and efficient operation of equipment, but also effectively control noise, meeting the development needs of modern manufacturing industry. With the deepening of industrial upgrading, these high-quality gearbox parts will have a broader application prospect and make greater contributions to the development of the machinery industry.