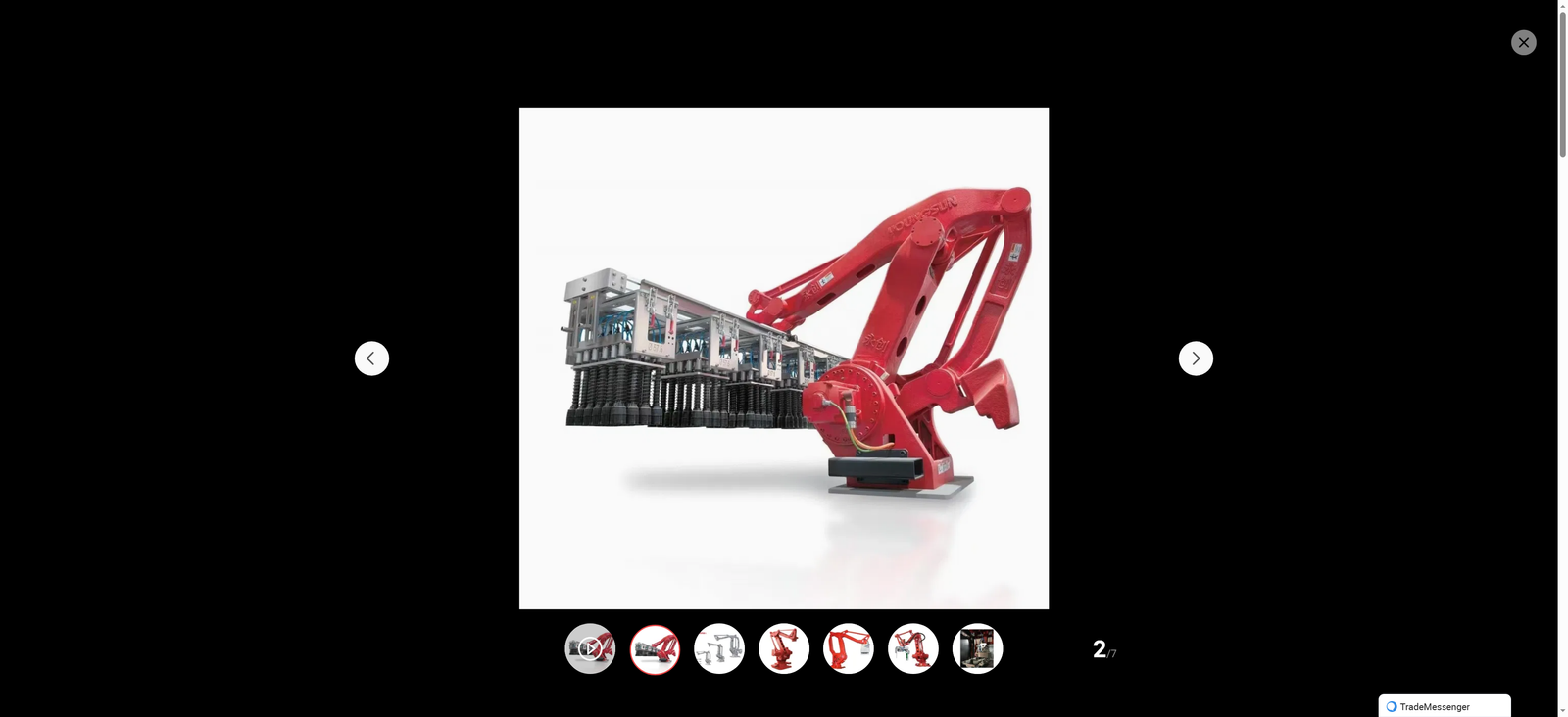

YSR-4-40-F 1900 Automatic Stacking Machine with Robot Palletizer: Redefining Efficient and Intelligent Palletizing Solutions

In the era of rapid development of intelligent manufacturing, the demand for efficient, stable and flexible logistics handling and packaging equipment is increasingly prominent. As a core equipment in the end link of the production line, automatic stacking machines play a vital role in improving production efficiency, reducing labor costs and ensuring stacking quality. The YSR-4-40-F 1900 Automatic Stacking Machine with Robot Palletizer, with its advanced technical design, excellent performance configuration and wide application adaptability, has become a benchmark product in the field of automatic palletizing, helping enterprises realize the transformation and upgrading of intelligent production.

The YSR-4-40-F 1900 Automatic Stacking Machine with Robot Palletizer is a high-end intelligent equipment integrating mechanical structure, electrical control, robot technology and software system. It is independently developed and designed for the pain points of low efficiency, high labor intensity, poor stacking stability and difficult quality control in traditional manual palletizing and semi-automatic palletizing. It adheres to the design concept of "efficiency first, stability first, intelligence leading and flexibility adaptation", and has achieved a comprehensive breakthrough in technical indicators and application performance.

In terms of core performance, the YSR-4-40-F 1900 has obvious advantages that are difficult to match by similar products. First of all, in terms of stacking efficiency, the equipment is equipped with a high-performance industrial robot and an optimized motion control algorithm. The maximum stacking speed can reach 40 pieces per minute, which is 3-5 times that of manual palletizing. It can continuously work 24 hours a day without fatigue, greatly improving the overall operation efficiency of the production line. Secondly, in terms of stacking accuracy, the equipment adopts high-precision positioning sensors and closed-loop control system, with a repeated positioning accuracy of ±0.5mm. It can ensure that each piece of goods is accurately placed in the specified position, the stacking is neat and firm, and the risk of goods collapse during storage and transportation is effectively reduced. In addition, the equipment has a strong load-bearing capacity, with a maximum single-piece load of 1900kg, which can meet the palletizing needs of large and heavy goods in various industries, and has strong adaptability to different specifications and types of goods.

In terms of structural design, the YSR-4-40-F 1900 adheres to the principles of rationality, durability and easy maintenance. The main body of the equipment adopts high-strength steel structure, which has been subjected to strict stress analysis and anti-fatigue test, ensuring the stability and service life of the equipment in long-term high-intensity operation. The robot arm adopts a lightweight design on the premise of ensuring strength, which reduces the energy consumption of motion and improves the response speed. At the same time, the equipment is equipped with a modular design, which divides the functional parts such as feeding, conveying, stacking and pallet output into independent modules. This not only facilitates the installation and debugging of the equipment, but also reduces the difficulty of later maintenance and repair. When a certain module fails, it can be replaced and maintained independently without affecting the operation of the entire production line, effectively reducing the downtime loss of the enterprise.

Intelligence is another core highlight of the YSR-4-40-F 1900. The equipment is equipped with an advanced industrial control system and a human-machine interaction interface. The operation interface adopts a 10-inch touch screen, which is intuitive and simple, and can be easily operated without professional technical training. The system has powerful functions such as parameter setting, process monitoring, fault alarm and data statistics. Operators can set different stacking parameters according to different goods specifications and stacking requirements, and the equipment can automatically complete the stacking operation according to the set program. At the same time, the system can real-time monitor the operation status of each part of the equipment, and once a fault occurs, it will immediately issue an audible and visual alarm and display the fault location and cause on the interface, which is convenient for operators to quickly troubleshoot. In addition, the equipment supports data connection with the enterprise's MES system, which can realize real-time synchronization of production data such as stacking quantity, operation efficiency and equipment status, providing data support for the enterprise's production management and decision-making.

The YSR-4-40-F 1900 Automatic Stacking Machine with Robot Palletizer has a wide range of application scenarios, and can be widely used in industries such as building materials, food and beverage, chemical industry, logistics and warehousing, and automobile parts. In the building materials industry, it can be used for palletizing of cement bags, ceramic tiles, gypsum boards and other goods; in the food and beverage industry, it can complete the automatic stacking of cartons, plastic bottles and cans; in the chemical industry, it can adapt to the palletizing needs of chemical barrels, chemical bags and other special goods; in the logistics and warehousing industry, it can realize the rapid stacking and sorting of goods, improving the efficiency of warehousing operations. The equipment can adapt to different types of pallets, such as wooden pallets, plastic pallets and paper pallets, and can complete various stacking forms such as cross stacking, staggered stacking and layered stacking, fully meeting the personalized needs of different enterprises.

In addition to excellent performance and wide adaptability, the YSR-4-40-F 1900 also pays great attention to safety and environmental protection. The equipment is equipped with a complete safety protection system, including safety doors, emergency stop buttons, safety light curtains and other devices. When the operator enters the dangerous area during the operation of the equipment, the equipment will immediately stop running to ensure the personal safety of the operator. At the same time, the equipment adopts energy-saving motors and optimized power control system, which effectively reduces energy consumption. Compared with traditional equipment, the energy saving effect is more than 20%. In addition, the noise of the equipment during operation is less than 75 decibels, which meets the national environmental protection standards and creates a comfortable working environment for the operator.

For enterprises, introducing the YSR-4-40-F 1900 Automatic Stacking Machine with Robot Palletizer is not only a replacement of equipment, but also a transformation of production mode. It can help enterprises reduce a lot of manual labor, save labor costs and management costs; improve stacking efficiency and product quality, enhance the market competitiveness of enterprises; reduce the risk of safety accidents caused by manual operation, and improve the level of production safety management; realize the intelligent monitoring and management of production data, and lay a foundation for the digital transformation of enterprises. In the long run, the investment in this equipment can bring considerable economic benefits and social benefits to the enterprise.

In the face of the increasingly fierce market competition and the accelerating pace of intelligent transformation, the YSR-4-40-F 1900 Automatic Stacking Machine with Robot Palletizer, with its excellent performance, intelligent design and perfect service, has become a reliable partner for enterprises to realize efficient and intelligent production. In the future, with the continuous progress of technology, the equipment will be continuously upgraded and optimized to provide more high-quality, efficient and intelligent palletizing solutions for more industries, and make greater contributions to the development of the global intelligent manufacturing industry.